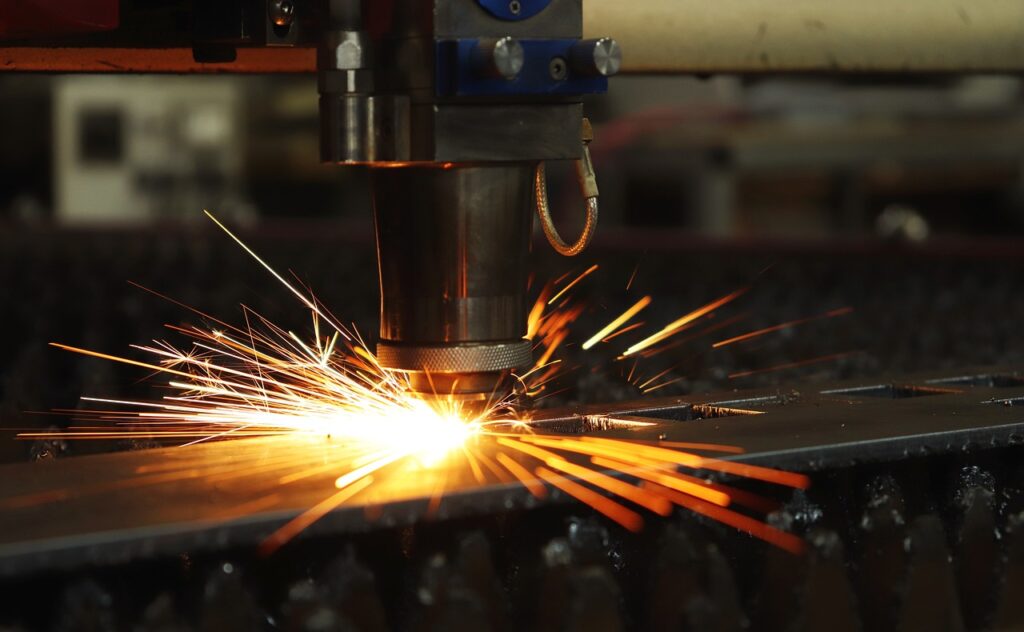

Machine safeguarding is the practice of protecting workers from injuries caused by operating machines that have moving parts or functions. The process involves installing shields or devices that cover the hazardous areas of a machine, such as ingoing nip points, rotating parts, flying chips, or sparks. It also requires manufacturers to following proper safety procedures including machine inspection and maintenance, use of PPE, and thorough training.

We’re Safeguarding Specialists

A mechanical engineer expert can assist with machine safeguarding investigations. Why? Because we have the expertise and experience to evaluate the design, performance, and compliance of the machines. We help identify the causes, effects, and solutions of machine-related problems or issues, such as product defects, accidents, or disputes. In addition, our team of experts can also provide technical advice, analysis, and reports on machine safety standards, regulations, and best practices.

Your First Line of Defense

Law firms, insurance companies, and manufacturers benefit from partnering with a team of experts for machine safeguarding investigations. We’re your first line of defense because we:

- Gain a comprehensive and objective understanding of the technical aspects of the machine-related problems.

- Understand how issues impact the legal, financial, and operational outcomes.

- Help reduce the costs, risks, and uncertainties associated with machine-related problems by finding effective, efficient ways to prevent, resolve, or improve them.

Enhance your credibility, reputation, and trustworthiness by partnering with SpecTest Forensics and our team of safeguarding specialists. We’re located in Atlanta, Georgia and work with clients across the U.S.